Category List

-

All Categories

-

All Categories

-

New Arrivals

New Arrivals Clearance

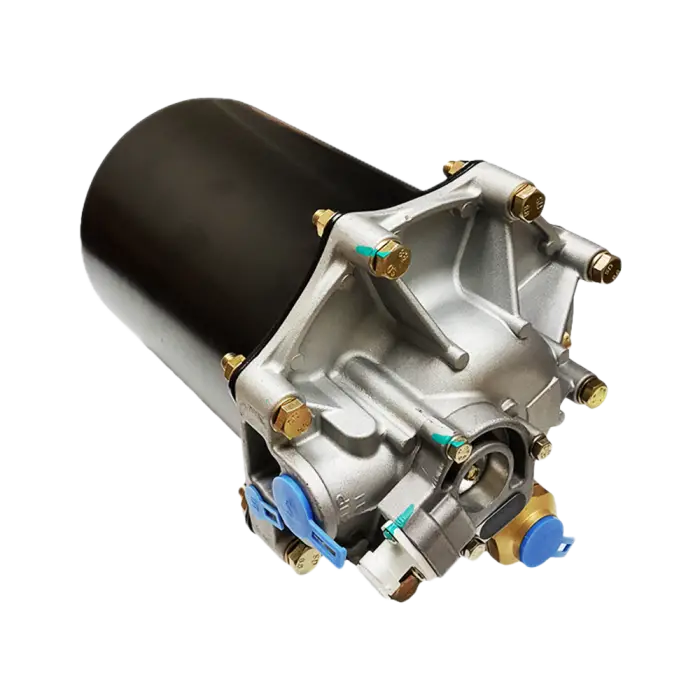

Clearance Air Brake Components

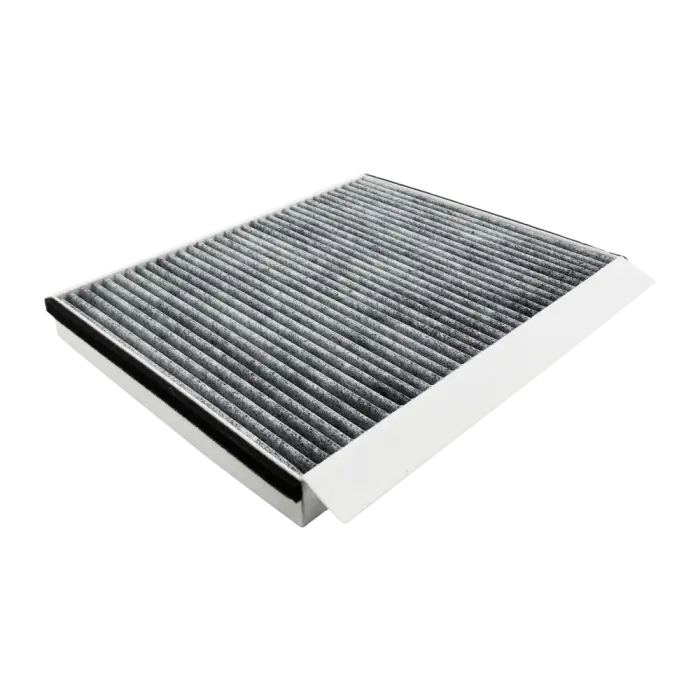

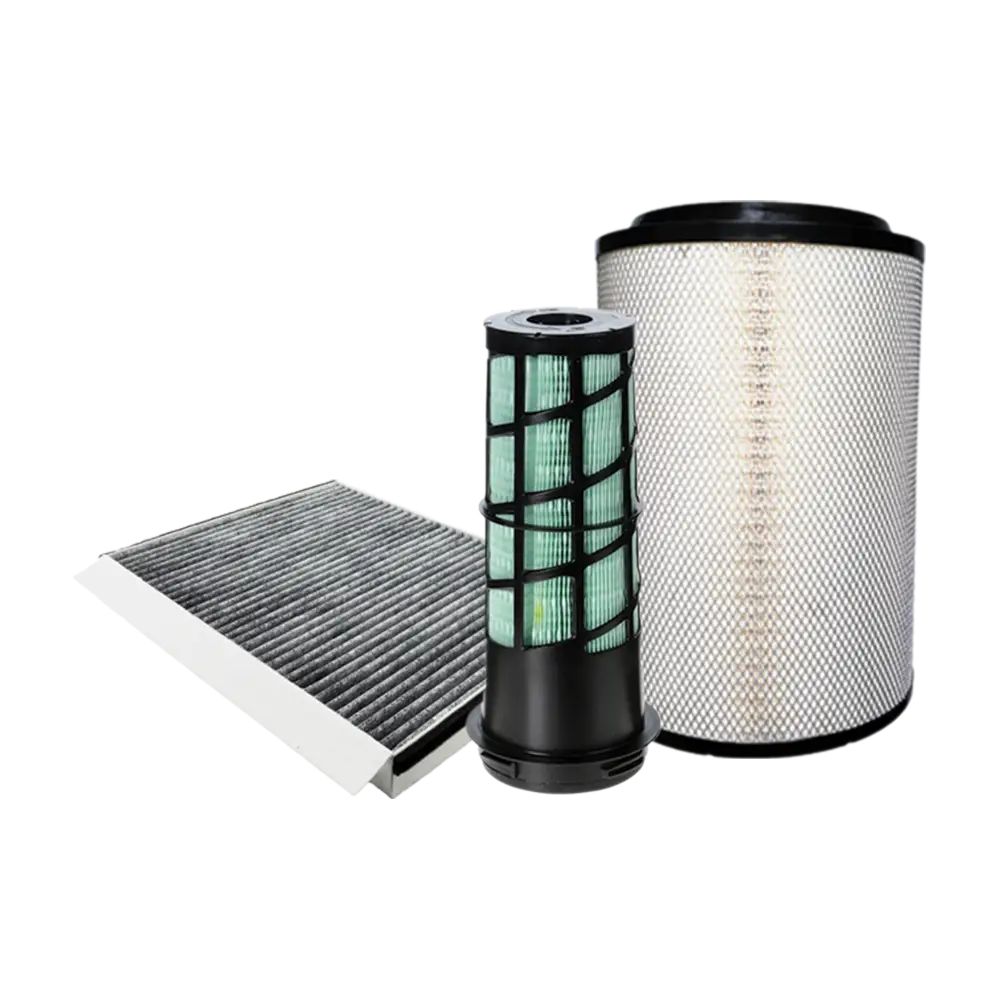

Air Brake Components Air Filters

Air Filters Air Springs

Air Springs Air Tanks

Air Tanks Body Parts

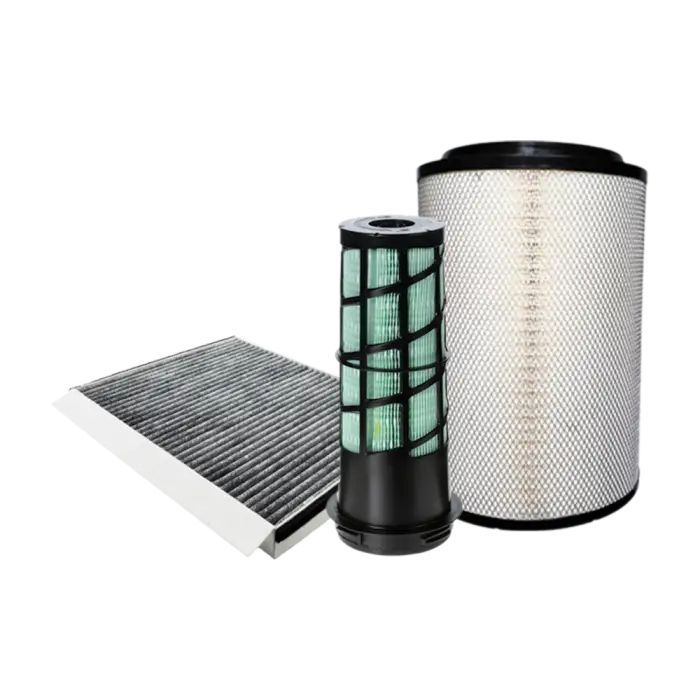

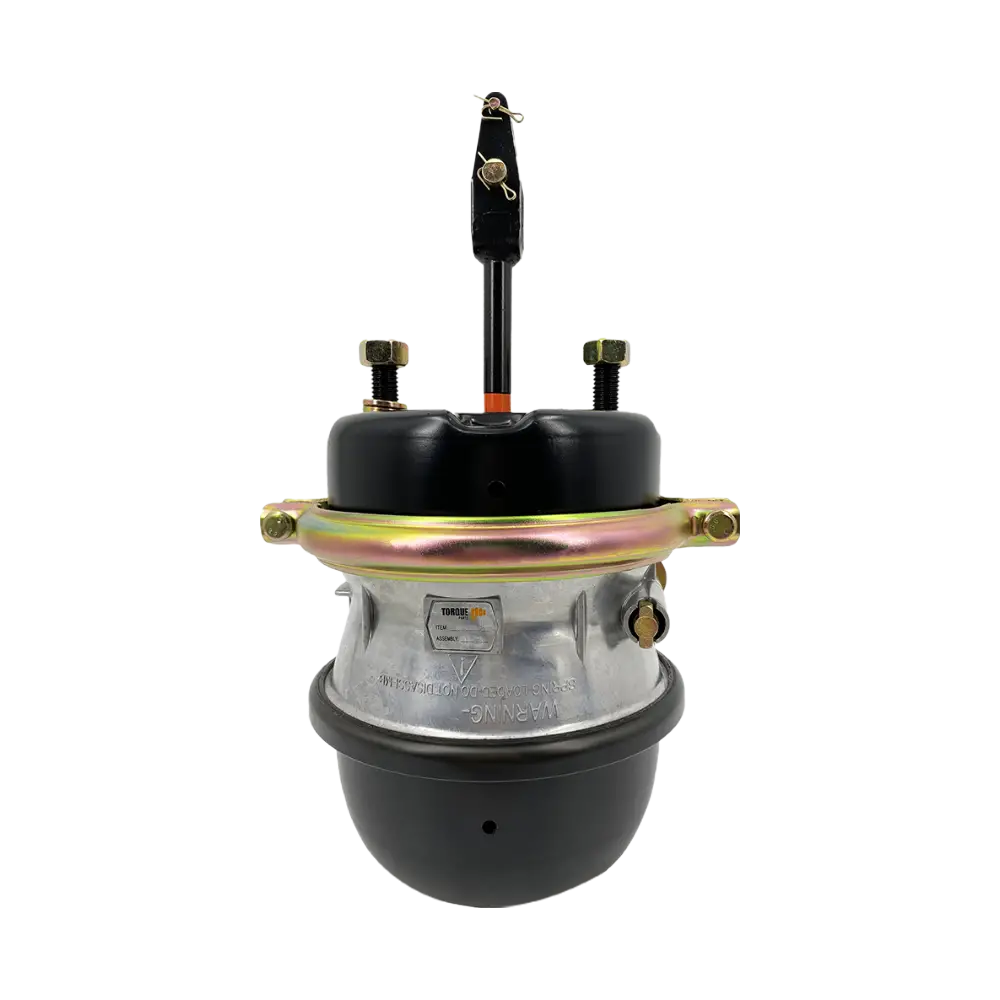

Body Parts Brake Chambers

Brake Chambers Cables & Coils

Cables & Coils Cargo Stabilizer

Cargo Stabilizer Hardware and Fittings

Hardware and Fittings Hoses & Clamps

Hoses & Clamps Mud Flap Hangers and Fenders

Mud Flap Hangers and Fenders Oils, Fluids and Chemicals

Oils, Fluids and Chemicals Power Take Offs

Power Take Offs Suspension Support Kits

Suspension Support Kits Suspension & Steering

Suspension & Steering Shock Absorbers

Shock Absorbers Slack Adjusters

Slack Adjusters Truck Accessories

Truck Accessories Wheel End Components

Wheel End Components Promotional Items

Promotional Items